Hey guys, this is the announcement that you've all been waiting for.

The PT-1 Pedal set will be released on June 1st 2015 at 12 noon EDT. Once that date arrives, we will be throwing the switch on our website, and these pedals will be available for immediate purchase.

A few reminders:

1) Make sure that you register on our website in order to make the checkout process a lot smoother (you need to register in order to purchase our products)

2) The curved pedal faces will also be available once the pedals are released. You will be able to purchase them at the same time.

3) Make sure that you read the Terms of Service and warranty carefully. You will have to agree to these when you check out.

4) The PT-1 pedal set will be limited to 1 set per customer. No exceptions.

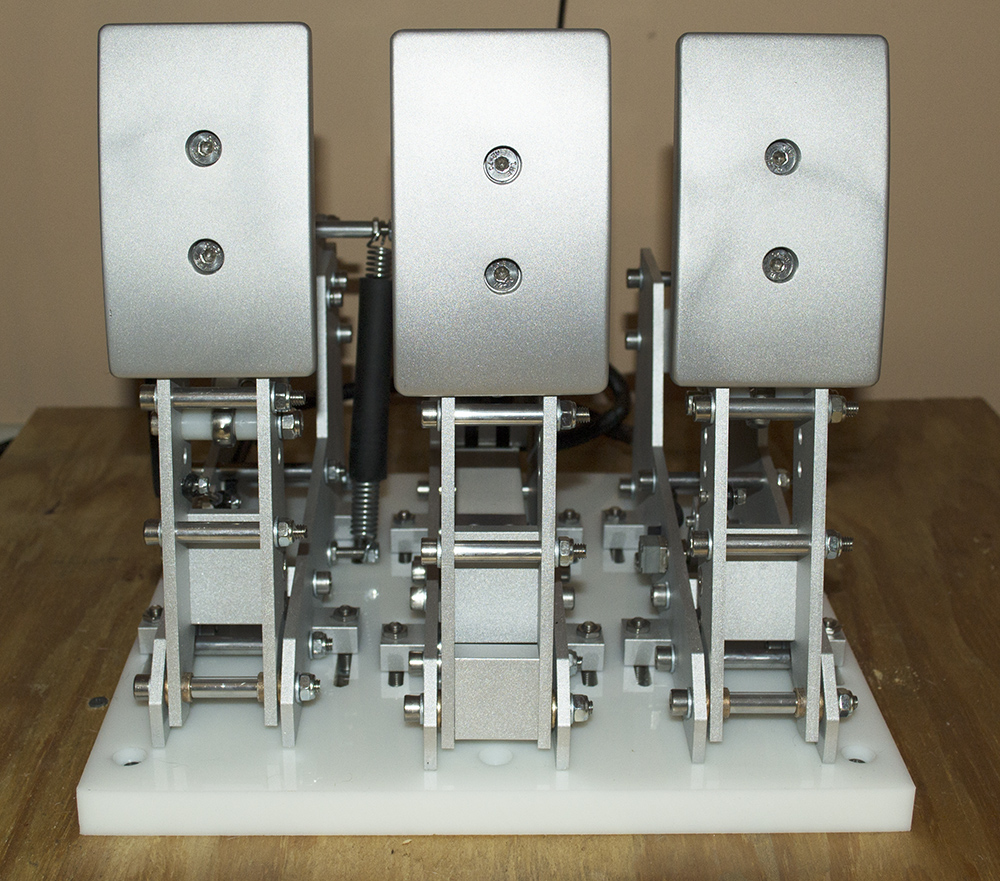

PT-1 Pedal set Features:

● Aluminum and Stainless Steel Construction

● 50KG Load Cell – Brake Pedal

● Industrial Quality Potentiometers (rated for millions of turns) – Throttle and Clutch Pedals

● Multiple Pedal Face Positions

● Adjustable Pedal Height

● Adjustable Spring Tension

● Adjustable Pedal Travel

● Adjustable Potentiometer Travel

● Adjustable Clutch “Feel”

● Can Be Inverted or Placed Right Side Up (with each pedal separately)

● Many More...

We are very proud of what we've accomplished over the past 3 years. Even though we've had multiple setbacks, and things haven't gone as smoothly as we would have liked, we took that extra time to improve upon things that we felt warranted improvement. We've said this multiple times, but it's always better to take the time to get things right. We've only got one shot at making a good impression with the public, and even though our pedals aren't 100% perfect (nothing in this world is), we now feel that they're ready to finally find their new homes.

This is our very first product. We don't have a wealth of experience in the areas of business or manufacturing. With that said, we've tried to do our best to give you a product that is reliable, durable, and adjustable in many different ways. We hope that our customers will enjoy our products for as long as they own them.

Along with this announcement, we've finally released the "Adjustment" series of videos. We've developed a separate page on our website called "PT-1 Adjustments", which can be found by mousing over the "PST" menu item at the top of our homepage and choosing "PT-1 Adjustments" from the drop-down menu. On this page you will find three separate videos, each discussing a different pedal. We have also provided time-stamps that should allow you to find the section you are most interested in.

We created these videos for the sole purpose of helping the public make adjustments to their pedals. We have tried to be as detailed as possible, but that doesn't mean that we haven't left something out. If you find that there is something you do not understand, or you'd like for us to make a notation at some point in the video, please let us know. We want to be sure that you have as much information as possible.

On a more personal note, I would like to thank a few people:

First and foremost, I'd like to thank my father for sticking with me throughout some of the most difficult times these past three years. He has not only been responsible for most of the financial support, but has supported any and all ideas surrounding this project. Without him, none of this would have been possible. Thanks, dad.

I also want to throw out a special thanks to Martin Enzmann ( aka - "The Details Man"), our beta tester. We really struck gold with Martin. When I first contacted Martin last spring, I had no idea how valuable he would ultimately turn out to be. His feedback regarding the design and functionality of our prototype pedals, has helped us to make improvements on certain mechanical portions of our PT-1 pedal set. We never expected the level of detailed feedback that Martin would eventually give us. On top of that, he has become a good friend. Thank you, Martin.

And last, I'd like to thank the community for all of the kind words of encouragement. We started our YouTube channel back in November of 2013. After posting the very first video in the iRacing forums, the feedback was overwhelmingly positive. I'm very grateful to be a part of this community, and no matter what the public thinks of our pedal set, I'm certain I always will be.

A few others I'd like to say "Thank you" to:

Slaven Corluka (my old modding buddy)

Darin Gangi (For allowing us to promote ourselves in the ISR forums)

All my fellow members of Virtua_LM (thanks for giving my 3D skills a shot!)

Shaun Cole (thanks for the article last summer!)

Shawn Purdy (one hellavu web developer ;-) )

DSD (for the circuit boards)

Chris Smith - Co-Founder - ProtoSimTech

http://www.protosimtech.com

)